Adresse

Infodoc : Réseau des bibliothèques et centres de documentation d'AgroParisTechFrance

contact

Catégories

|

Thésaurus Agro-alimentaire , PHYSIQUE , PARAMETRE PHYSIQUE , DENSITE

DENSITESynonyme(s)POIDS SPECIFIQUE |

Documents disponibles dans cette catégorie (18)

Ajouter le résultat dans votre panier Faire une suggestion Affiner la recherche Interroger des sources externes

Ajouter le résultat dans votre panier Faire une suggestion Affiner la recherche Interroger des sources externes

Livre

Livre

Livre

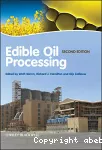

Livre978-1-4443-3684-91 vol. (XIX-322 p.)

1 vol. (XIX-322 p.)ISBN : 978-1-4443-3684-9

Livre115,15

Livre115,15978-0-306-47806-2372 p.

372 p.Prix : 115,15 ISBN : 978-0-306-47806-2

Livre

Livre978-0-87819-509-1552 p.

552 p.ISBN : 978-0-87819-509-1

Livre751

Livre751978-0-12-384430-9919 p.

919 p.Prix : 751 ISBN : 978-0-12-384430-9

Livre1350

Livre1350978-2-85206-999-21 vol. (XVIII-1474 p.)

1 vol. (XVIII-1474 p.)Prix : 1350 ISBN : 978-2-85206-999-2

Livre

Livre978-0-12-398530-91 vol. (XXIII-867-[8] p.)

1 vol. (XXIII-867-[8] p.)ISBN : 978-0-12-398530-9

Livre

Livre978-1-4398-0918-11 vol. (XXIII-697 p.)

1 vol. (XXIII-697 p.)ISBN : 978-1-4398-0918-1

Livre650,7

Livre650,7978-2-12-197621-1256 p.

256 p.Prix : 650,7 ISBN : 978-2-12-197621-1

Thèse17 p. - 133 p.

Thèse17 p. - 133 p.

17 p. - 133 p.

Livre

Livre

Livre59,61

Livre59,61978-0-387-30780-X257 p.

257 p.Prix : 59,61 ISBN : 978-0-387-30780-X

Livre

Livre978-3-527-26218-2465 p.

465 p.ISBN : 978-3-527-26218-2

Livre500

Livre500978-2-86883-052-4845 p.

845 p.Prix : 500 ISBN : 978-2-86883-052-4

Livre

Livre978-0-8169-9875-31 vol. (XIII-762 p.)

1 vol. (XIII-762 p.)ISBN : 978-0-8169-9875-3

Livre39 EUR

Livre39 EUR978-2-7430-0510-81 vol. (XIV-199 p.)

1 vol. (XIV-199 p.)Prix : 39 EUR ISBN : 978-2-7430-0510-8

Livre50,35

Livre50,35978-80-902671-7-692 p.

92 p.Prix : 50,35 ISBN : 978-80-902671-7-6